Robots are roaming on construction sites! Yes you read it right!!

Hailing to a world where construction industry is no longer facing any hurdle by the boundaries of human competence.

Embracing the era of automation, construction robotics is breaking the myth that the construction industry lags in many ways when it comes to adopting advanced technologies. The entry of Robotics in construction is a true testament where innovation & technology meet to shape the future of buildings. After the decades of implementing the same conventional methods & techniques, today the construction industry is heading toward streamlined process with the help of Robotics. Leveraging robots is helping in skyrocketing the efficiency & productivity within the industry.

Between the bricks and beams, robotics painting a novel design of proficiency & progress to the ever-growing home of construction, Automated Construction Equipment

As the technological transformation of industry is moving forward, integration of robots in construction are becoming an inevitable contributor to industry’s advancement. In this article, we will take a look at advanced robotic applications in construction industry and its impact on the construction realm.

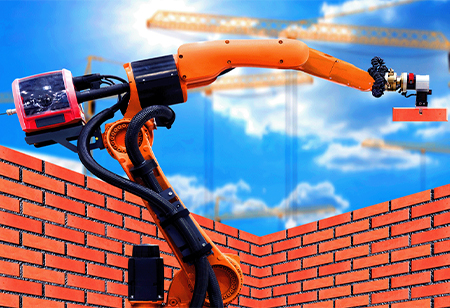

Bricklaying Robots: Days are gone where brick laying was laborious task for masons. Visualize that you are walking on the construction site and seeing a robotic worker laying the bricks, one by one with accurate precision. Yes, Robots have infiltrated the construction industry and henceforth have proved that technology can do anything, anytime, anywhere. Automated bricklaying robots have been designed and developed to lay the bricks in construction site swiftly and precisely. These inventive brick layers can work endlessly without getting tired and their work is quick & error-free. Robots are seamlessly enhancing the construction by analyzing the site of construction, computing the finest position of bricks and simultaneously they adjust their body movements in order to align the bricks properly. It reduces the requirement for manual workers and increase productivity by handling the intricate patterns & variations of bricks. Nowadays, construction companies are using the bricklaying robots to achieve maximum efficiency and precision in projects.

Bricklaying Robots: Days are gone where brick laying was laborious task for masons. Visualize that you are walking on the construction site and seeing a robotic worker laying the bricks, one by one with accurate precision. Yes, Robots have infiltrated the construction industry and henceforth have proved that technology can do anything, anytime, anywhere. Automated bricklaying robots have been designed and developed to lay the bricks in construction site swiftly and precisely. These inventive brick layers can work endlessly without getting tired and their work is quick & error-free. Robots are seamlessly enhancing the construction by analyzing the site of construction, computing the finest position of bricks and simultaneously they adjust their body movements in order to align the bricks properly. It reduces the requirement for manual workers and increase productivity by handling the intricate patterns & variations of bricks. Nowadays, construction companies are using the bricklaying robots to achieve maximum efficiency and precision in projects.

PaceRobotics, an ingenious robotics company based in Bangalore, incubated by SINE-IIT Bombay & backed by Pidilite Industries to design and deploy construction robots for building projects with real estate builders & contractors. Currently they are building Modular Wall Finishing Robot for automated wall finishing tasks like brick layering, plastering, putty and painting.

Drones for Surveying & Inspections: The dawn of Robotic drones inspection on construction site is making a momentous shift in the way builders & industries carrying out inspection in their operations. They quickly map the construction site and identify potential issues and monitor the progress.

Drones for Surveying & Inspections: The dawn of Robotic drones inspection on construction site is making a momentous shift in the way builders & industries carrying out inspection in their operations. They quickly map the construction site and identify potential issues and monitor the progress.

They are equipped with high resolution cameras and sensors to survey construction sites & inspect the structures. Drones capture aerial images and collect data to supply valuable insights for planning, monitoring & quality control of projects.

These robotic drones enables more rapid and precise data collection that reduces the time & cost connected with conventional surveying methods in construction. Moreover, drones can also access the hard-to-reach spots and improve security & protection by lessening the need for workers to examine risky locations physically. On the whole, with advent of technological fiction, drones are transforming the mode of surveying and inspections in the construction industry.

According to Alok Bansal, Managing Director & Country Head, Visionet India “The adoption of automation is the future of every industry, large and small businesses, to increase efficiency, reduce costs and save time in an error-free process”.

Automated Construction Equipment: Whereas the scope of automation in construction industry is quiet broad, businesses are opting the ways for automating the dangerous tasks in the construction site. The tasks in construction industry are typically repetitive, physical, precise, manual and time consuming. Therefore, robots are used to operate the heavy construction machinery & equipment namely excavators & cranes. This automated robotics on site can perform the complicated construction tasks with correctness and accurateness which gradually reduces the scenario of reliance on manual labours. For instance, Robotic cranes, excavators & bulldozers are programmed to carry the heavy machineries and complete specific tasks. By leveraging the automated robotic construction equipment, companies & businesses can enhance the overall productivity and eliminate the human error on construction sites.

Automated Construction Equipment: Whereas the scope of automation in construction industry is quiet broad, businesses are opting the ways for automating the dangerous tasks in the construction site. The tasks in construction industry are typically repetitive, physical, precise, manual and time consuming. Therefore, robots are used to operate the heavy construction machinery & equipment namely excavators & cranes. This automated robotics on site can perform the complicated construction tasks with correctness and accurateness which gradually reduces the scenario of reliance on manual labours. For instance, Robotic cranes, excavators & bulldozers are programmed to carry the heavy machineries and complete specific tasks. By leveraging the automated robotic construction equipment, companies & businesses can enhance the overall productivity and eliminate the human error on construction sites.

A prominent construction company in India, Larsen & Toubro (L&T) is embracing the realm of automated robotics in its operations. They have exploited the technology of robotics to enhance the productivity and to reduce the time consumption such as concrete spraying, material handling & operating.

Robotic Exoskeletons: Construction industry is known for hazardous risks and having high chances of injuries. By facilitating the workers to bear the heavy loads without needless strains, these wearable robotic Exoskeletons are augmenting the human abilities and enhancing the safety & productivity in the construction sites. Robotic exoskeletons are extraordinary wearable devices intended to augment the physical capabilities of workers & individuals. These Exoskeleton suits are worn to aid the construction labours in lifting heavy objects thereby reducing the risk of injuries. They can perform physically demanding tasks and reduce the strain on the workers muscles and joints. This disruption of Robotic exoskeletons in construction industry is not just a technology that reduces the risks of injuries but also empowers to facilitate productivity to accomplish the tasks efficiently & effectively.

Robotic Exoskeletons: Construction industry is known for hazardous risks and having high chances of injuries. By facilitating the workers to bear the heavy loads without needless strains, these wearable robotic Exoskeletons are augmenting the human abilities and enhancing the safety & productivity in the construction sites. Robotic exoskeletons are extraordinary wearable devices intended to augment the physical capabilities of workers & individuals. These Exoskeleton suits are worn to aid the construction labours in lifting heavy objects thereby reducing the risk of injuries. They can perform physically demanding tasks and reduce the strain on the workers muscles and joints. This disruption of Robotic exoskeletons in construction industry is not just a technology that reduces the risks of injuries but also empowers to facilitate productivity to accomplish the tasks efficiently & effectively.

For instance, Bangalore-based robotics venture, DiFACTO Robotics and Automation offers turnkey-based automation systems for various industries & applications including material handling, welding, and robot simulation and so on.

Autonomous Vehicles: Bringing robotics into construction is a smart choice ever in this digital era. Usually construction sites are situated close to the traffic and crowded areas. Hence the chances of accidents are high while transporting heavy materials on road by manually using conventional vehicles. The robotics or autonomous vehicles are being deployed for transporting materials on the construction sites. These self driving robots navigate to the entire construction site independently and reduce the need of operator or driver. Using these vehicles, companies are expediting the logistic facilities and streamlining the operational efficiency in construction sector. They have an exceptional capability to transport construction materials, tools, and equipment from one site to another site and optimize the workflow as well as reduce the downtime. The advanced autonomous vehicles are equipped with the technologies like GPS and in-built sensors that allow the robots to navigate into the site environment securely. By leveraging the use cases of robotic autonomous vehicles, construction companies are improving their core tasks in building logistics and speed-up the work efficiency on constructional sites.

Autonomous Vehicles: Bringing robotics into construction is a smart choice ever in this digital era. Usually construction sites are situated close to the traffic and crowded areas. Hence the chances of accidents are high while transporting heavy materials on road by manually using conventional vehicles. The robotics or autonomous vehicles are being deployed for transporting materials on the construction sites. These self driving robots navigate to the entire construction site independently and reduce the need of operator or driver. Using these vehicles, companies are expediting the logistic facilities and streamlining the operational efficiency in construction sector. They have an exceptional capability to transport construction materials, tools, and equipment from one site to another site and optimize the workflow as well as reduce the downtime. The advanced autonomous vehicles are equipped with the technologies like GPS and in-built sensors that allow the robots to navigate into the site environment securely. By leveraging the use cases of robotic autonomous vehicles, construction companies are improving their core tasks in building logistics and speed-up the work efficiency on constructional sites.

Tata Projects, a leading player in construction industry having project sites across the country, incorporates the applications of robotics in their operations. They have put into practice of robotic solutions for tasks like demolition, excavation, examine & monitor the construction sites.

At last, gone are the days of relying only on human labour to carry out demanding tasks on the construction site. With the helm of automated robotics, the progression of construction industry has been bumping up to newer heights of productivity & precision. These technological marvels have modernized the way we build the buildings and transforming the traditional practices.

Beyond productivity and safety, the advancements of robotics in construction contribute to sustainability efforts by optimizing the material usage and reducing wastes. With each & every advancement, we move forward to a future where construction sites are transformed into automated environments, and transfiguring the system to contour the world seamlessly around us!

We use cookies to ensure you get the best experience on our website. Read more...

Copyright © 2025 HomesIndiaMagazine. All Rights Reserved.